What is Pneumatic Conveying?

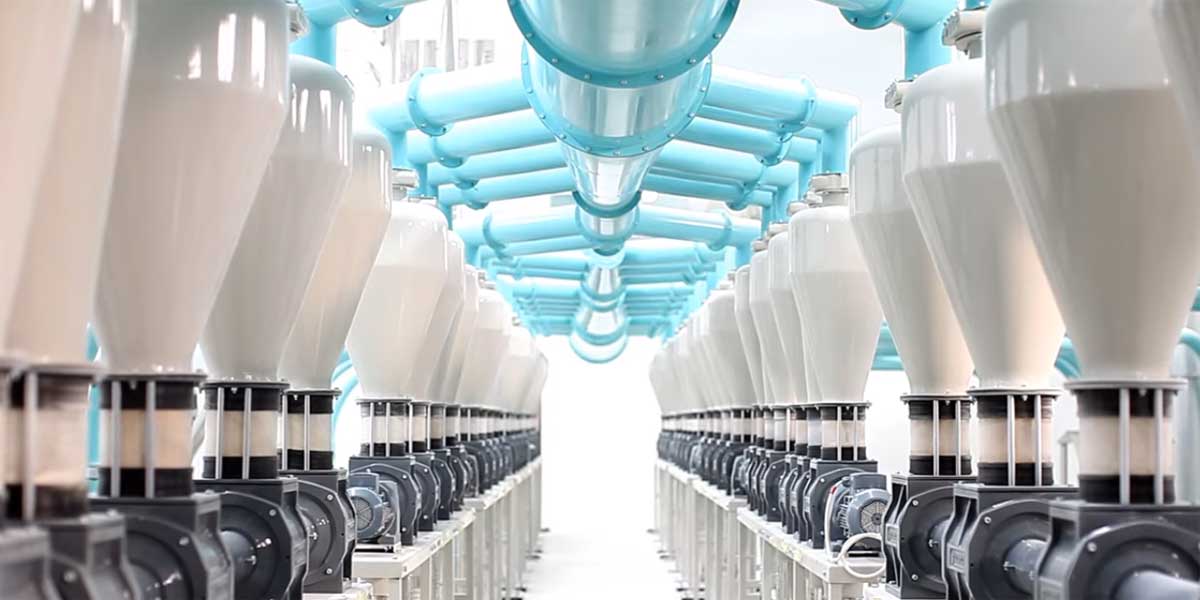

Pneumatic conveying also called as pneumatic transport is a system that works by means of air or gas. These systems are widely made use of in manufacturing plants and process industries for material handling through pipes.

A pneumatic conveying system consist of pipe lines, diverter valves, elbows, a feeding machine that is generally a rotary valve, pressurized or vacumized air or gas that is generated by a roots blower and a silo with filter. Although air is used in most systems, different gases should be used in such cases fire hazards, explosion risk, etc. Pneumatic transport systems are utilized for transport of granular and powdered materials through pipes by pressurized or vacumized air/gas in many industries.

Pneumatic transferring is a requested system by many industries. As a matter of fact, pneumatic conveying is requested in numerous industries in which material handling is necessary. Pneumatic transport may be done either by pressurized air or by vacuumized air. The roots blower pump is placed just before the feeding machine -it is commonly an air-lock - to give pressurized air or pressurized gas to system in pressure lines.

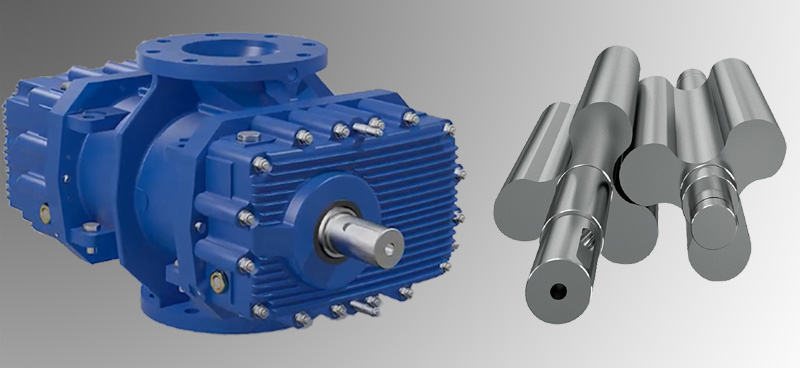

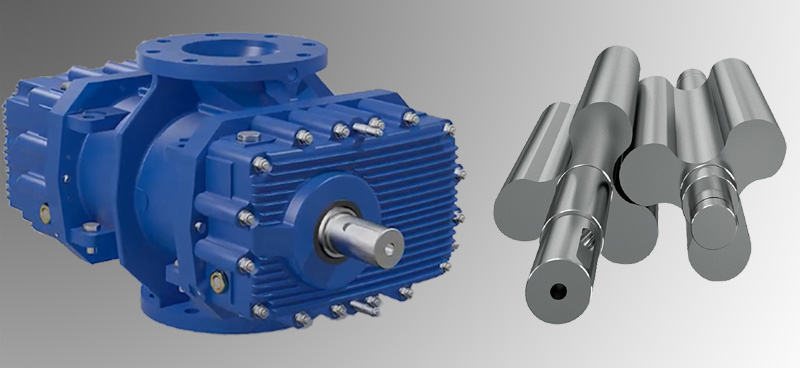

Roots blowers are vital machines to acquire required pressurized or vacuumized air and flow rate for conveying of bulk materials in pneumatic transport systems.

Pasifik Blower

How to choose the right Roots Blowers for a Pneumatic Conveying System?

Roots Blowers for Pneumatic Conveying at a Glance

The key point here is to be able to calculate correctly the right rotary lobe type air pump for the system. You do not have to worry about it. Pasifik Blower can calculate the right pneumatic conveying blower for your system.

We need some data as you can see listed items below to determine the rotary positive displacement blowers that what your system actually needs:

- The material to be transported,

- Specific gravity of the material,

- Particle diameter of the material,

- Horizantal and vertical length of the pipeline,

- Elbow (bend) number at pipeline,

- Inner diameter of pipes,

- Conveying capacity as tons per hour,

- Maximum air temperature,

- Altitude.

Each of the above items is crucial to find the right roots pumps so that the system can operate efficiently for many years. Blower calculation for pneumatic conveying systems is very important and it requires expertise, know-how and experience.

Roots Blowers are employed in many pneumatic conveying areas:

- Pneumatic conveying of foods,

- Pneumatic conveying of chemicals,

- Pneumatic conveying of plastics,

- Pneumatic conveying of flour,

- Pneumatic conveying of kiln,

- Pneumatic conveying of cement,

- Pneumatic conveying of ash,

- Pneumatic conveying of coal powder,

- Pneumatic conveying of lime stone,

- Pneumatic conveying of liquids,

- Pneumatic conveying of pulp,

- Pneumatic conveying of rock dusting,

- Pneumatic conveying of woor pellet,

- Pneumatic conveying of granular and powdered materials.

In addition to above list, there are numerous pneumatic conveying applications in which the roots blowers are used in many industries.

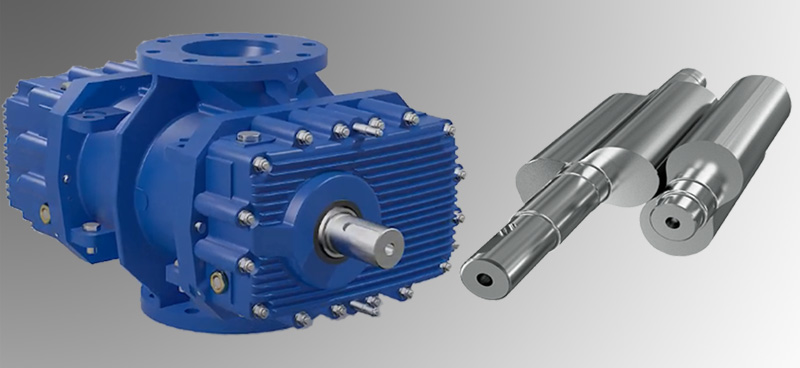

Three Lobes Roots Blowers

There are eight different tri-lobe roots blowers that we have produced with various capacities and dimensions.

Two Lobes Roots Blowers

There are eight different two lobe roots blowers that we have produced with various capacities and dimensions.

Related Articles about Roots Blowers Applications in Industry

Send a Message to Pasifik Blower