What is Thermoforming?

As the name suggests, thermoforming consists of combination of two technical terms: Thermo and Forming. Meaning in intension of thermo is heat and forming one is molding and pressing.

Thermoforming is an industrial application where thermoplastic sheet or film is turned into a new shape by means of heat and pressure. Heat is applied to plastic sheet until sufficient temperature where it will be soft or supple for forming. Then the soft plastic sheet is stretched a cool mold surface and pressure is applied. After the sheet is formed, cooling is applied to remove it from mold.

It should be considered that application of thermoforming differs from injection molding and compression molding.

As an interdisciplinary process thermoforming makes use of physics, mechanical engineering, materials, chemistry.

The roots blower pumps have a key role in thermoforming processes. They are utilized for accelerating mold surface cooling. They are also employed for quick early evacuation of molds.

Pasifik Blower

How to use roots blowers in thermoforming?

Roots Blowers for Cooling Mold Surface:

Mold surface cooling get accelerated by means of roots blowers. In other words, roots blower pumps are used to accelerate the cooling process of molds. Roots type blowers are also used in heavy-gaguge forming. Free surface is cooled by convecting air across it with blowers or by spraying water or mist. Air appliying is ten times more effective for removing heat than other methods. Water spraying is another effective method but it is not choosen because it causes rusting and electrical problems.

Roots Blowers for Vacuum Box and Vacuum System:

Primary task of vacuum system is to evacuate mold cavity air in a controlled manner and as quickly as possible. The vacuum system is applied in heavy-gauge thermeformers that be either individual for a machine or many machines. As for vacuum box, it is utilized behind the vacuum holes. Pressure drop and volume should be very low through the vacuum box. Positive displacement blowers are attached directly to the very deep molds for quick early evacuation.

As a result, the roots blower pumps have a key role in thermoforming processes.As a result, the roots blower pumps have a key role in thermoforming processes.

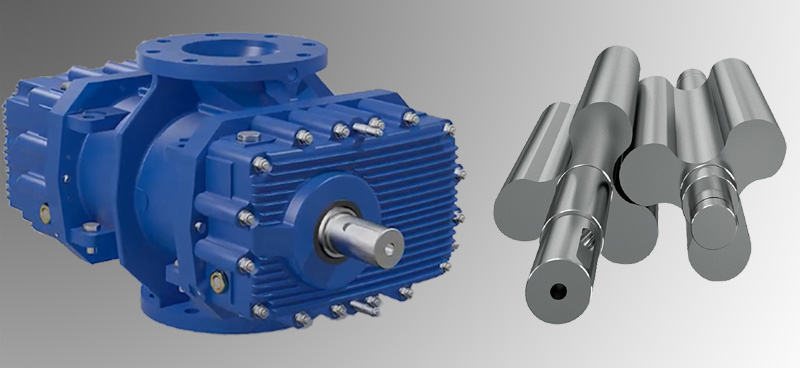

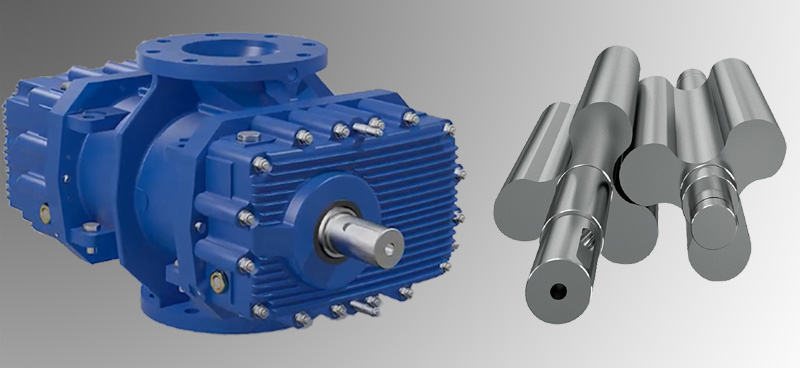

Three Lobes Roots Blowers

There are eight different tri-lobe roots blowers that we have produced with various capacities and dimensions.

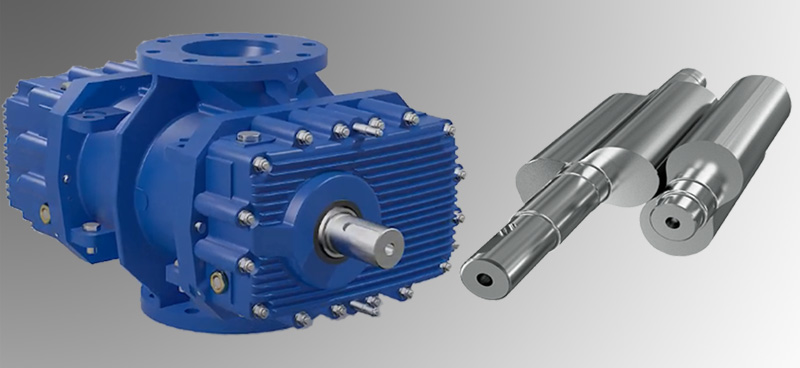

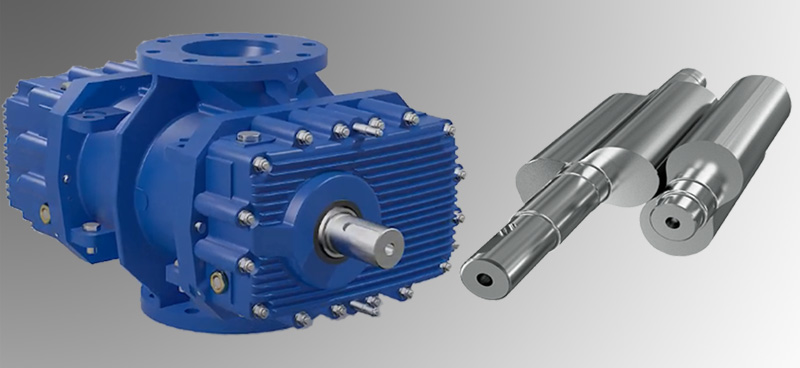

Two Lobes Roots Blowers

There are eight different two lobe roots blowers that we have produced with various capacities and dimensions.

Related Articles about Roots Blowers Applications in Industry

Send a Message to Pasifik Blower